Introduction

Conventional industrial wastewater pretreatment often suffers from complex treatment trains, high operating costs, and inconsistent performance—especially with high-hardness, high-silica, and high-suspended-solids feeds. Leveraging its proprietary PEK tubular membranes, Plum Membrane introduces an innovative membrane-based pretreatment solution. With a compact flowsheet and highly adaptable separation performance, it delivers stable softening, efficient impurity removal, low chemical dosing, and low operating costs—supporting long-term stable operation of downstream NF/RO systems and advancing advanced treatment and Zero Liquid Discharge (ZLD) goals.

Background & Challenges

In power, steel, and coal-to-chemicals industries, circulating cooling water and process wastewater typically exhibit high hardness, elevated silica, and high fluoride. Conventional pretreatment trains—clarifiers, multimedia filters, and hollow-fiber UF—require large footprints and heavy chemical consumption, and operate unreliably under high-SS and high-fouling loads. This leads to scaling and damage in downstream membrane systems, hindering the deployment of advanced membrane treatment and ZLD.

Process Overview

Leveraging proprietary PEK tubular membranes, Plum Membrane offers a compact, high-efficiency pretreatment solution for industrial wastewater. Upstream softening is carried out with alkaline reagents and sodium carbonate, followed by crossflow filtration through PEK tubular membranes to deliver rapid conditioning and stable treatment of high-hardness, high-silica streams. The scheme operates without conventional coagulants or flocculants, features a compact footprint and a high level of automation, and is particularly suited to complex wastewaters with heavy suspended-solids loading and frequent variability.

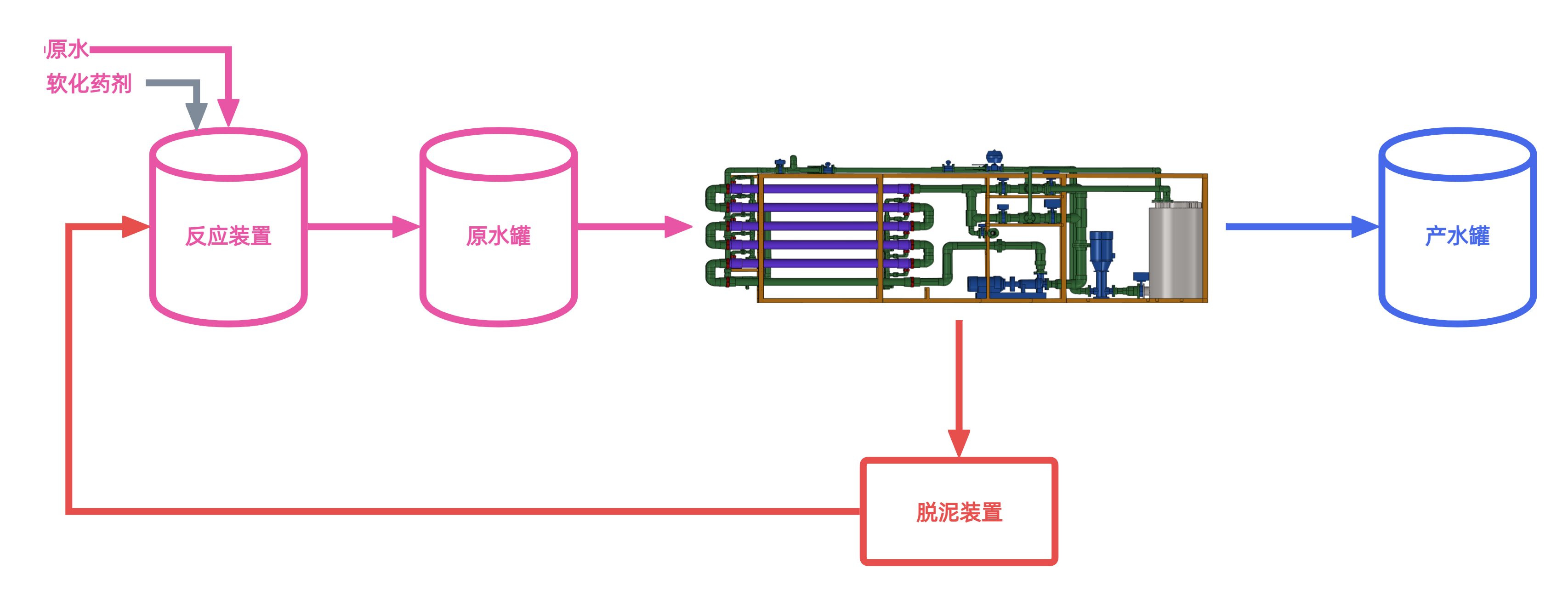

Process Flow

Raw water is dosed with alkaline reagents (e.g., NaOH or lime) and sodium carbonate to adjust pH to 11–12, precipitating calcium/magnesium hardness and silica. The softened stream feeds directly to the PEK tubular membrane unit; its high flux and robust antifouling performance enable efficient solid–liquid separation. Permeate hardness is consistently ≤50 mg/L and total silica ≤10 mg/L; after pH adjustment, the permeate proceeds directly to downstream NF or RO. The concentrate is routed to sludge thickening and dewatering; cake is hauled off-site, while filtrate is returned to the softening tank. The overall scheme achieves a practical recovery approaching 100%, significantly improving resource recovery and effluent stability.

Process Flow Comparison

This pretreatment scheme applies front-end alkalization (NaOH or lime) with sodium carbonate for pH control to precipitate hardness and silica, followed by crossflow filtration on PEK tubular membranes for rapid solids removal. The permeate feeds directly to downstream NF/RO. Compared with conventional clarifier + multimedia filtration + hollow-fiber UF trains, the PEK-based scheme is far simpler: no coagulants/flocculants, a more compact footprint, shorter process line, higher automation, easier operation, and simpler maintenance. In conventional softening, neutral backwash and rinse streams from UF/MMF must be recycled to the softening reactor, consuming ~15–20% more acid/alkali, increasing system salinity and reagent usage, and raising downstream membrane CAPEX/OPEX.

Technical Highlights

Core Advantages

Economic Benefits

Applications

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China