Introduction

Landfill leachate is a complex, high strength wastewater featuring elevated ammonia, high salinity, and a low C/N ratio; in aging landfills it is often unsuitable for conventional biological treatment. To achieve nitrogen reduction, upgraded effluent quality, and resource recovery, Plum Membrane has developed a full scale treatment scheme centered on ammonia stripping.

Background & Challenges

Typical Feed Water Characteristics

Process Flow

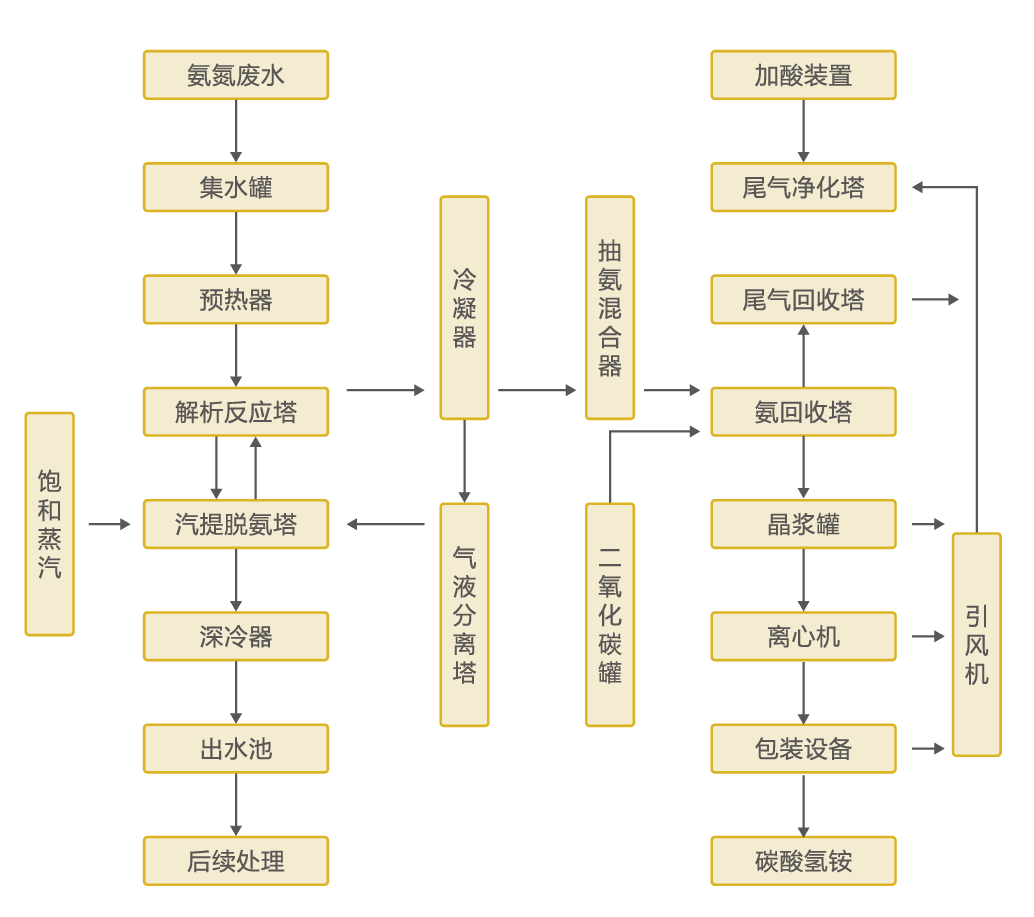

High-ammonia wastewater is first collected in a storage tank and preheated via a heat exchanger before entering the desorption reactor. There, it is heated with saturated steam to facilitate the release of ammonia nitrogen from the liquid phase into the gas phase. The wastewater then flows into the ammonia stripping tower, where enhanced gas-liquid contact ensures efficient ammonia removal. The stripped liquid is cooled by a deep cooler and sent to a product water tank for further treatment or discharge.

The ammonia gas released during desorption is cooled by a condenser. In the gas-liquid separation tower, uncondensed gases and condensate are separated. The condensate is recirculated, while uncondensed ammonia gas is sent to an ammonia absorber and then reacted with carbon dioxide in a carbonation tower to produce ammonium bicarbonate slurry. This slurry enters a crystal tank, where it undergoes centrifugal separation and packaging to yield a recoverable ammonium bicarbonate product. The remaining tail gas passes through acid dosing, tail gas scrubbing, and recovery units before discharge. A draft fan ensures system stability and prevents gas leakage.

This process achieves high ammonia removal efficiency (≥75%) and converts ammonia into a reusable by-product, ammonium bicarbonate, significantly reducing downstream treatment loads and operational costs, supporting full leachate treatment, resource utilization, and near-zero discharge goals.

Design Influent and Effluent Water Quality

|

No. |

Parameter |

Unit |

Influent |

Effluent |

Removal |

|

1 |

NH₃ N |

mg/L |

≤3500 |

≤875 |

≥75 % |

|

2 |

TN |

mg/L |

≤4300 |

≤1675 |

≥61 % |

|

3 |

pH |

— |

6 – 9 |

6 – 9 |

— |

Process Highlight

Applications

Case Photos

Landfill Leachate Treatment – Ammonia Stripping Process

Landfill Leachate Treatment – Ammonia Stripping Process

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China