Introduction

In industrial wastewater and reuse water treatment, high suspended solids (SS) and colloidal particle content often cause subsequent membrane systems to be prone to clogging, unstable operation, and increased maintenance costs. Plum Membrane's tubular membrane suspended solids removal solution adopts high-strength, pollution-resistant PEK tubular membranes, suitable for long-term stable operation in high suspended solids, high-concentration systems, without conventional flocculation sedimentation and sand filtration cumbersome processes. The solution has a short process, high automation, removal rate up to 99%, significantly enhancing subsequent system operational safety and overall water recovery rate, applicable to pretreatment links for various industrial wastewater, concentrated brine, and reuse water.

Process Overview

This solution employs PEK tubular membranes with superior anti-pollution capability and strong chemical cleaning compatibility. It is designed for treating fluids with suspended solids (SS) concentrations up to 30–50 g/L. The system runs without backwashing, especially suitable for pretreatment of nanofiltration (NF) or reverse osmosis (RO) membrane processes. Typical applications include solid-liquid separation and clarification in biological fermentation, natural product extraction, food and beverage production, and resource recovery scenarios.

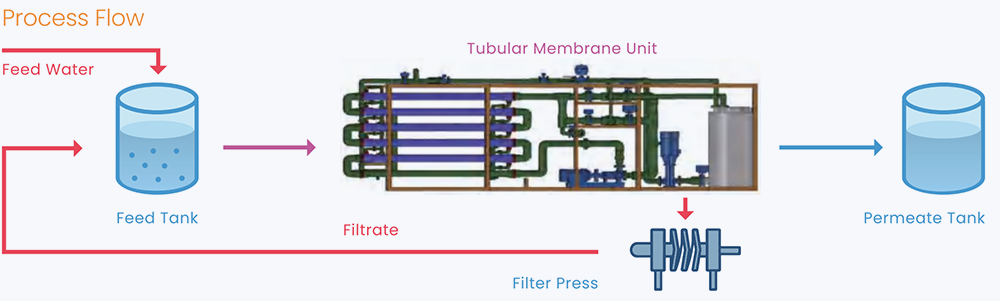

Process Flow

Feed water first enters a buffer tank (recommended retention time ≥1 hour). The wastewater is then pumped into the tubular membrane system for cross-flow filtration.

▪ Permeate flows to the permeate buffer tank.

▪ Concentrate flows to a sludge thickening tank.

▪ System recovery rate: 90–98% in a single pass.

▪ The concentrate is dewatered, with the filtrate recycled back to the raw water tank and the sludge transported off-site.

▪ Aside from water carried away with the sludge, the actual water recovery rate approaches 100%.

▪ The system adopts an N+1 configuration: N units in operation, 1 unit for standby/cleaning, ensuring 24/7 continuous operation.

Process Highlights

Applications

Case Photos

Clarification and protein removal from fermentation broth

Impurity removal from semiconductor grinding wastewater

Clarification of PV monocrystalline silicon grinding wastewater

Clarification and protein removal from fermentation broth

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China