Introduction

High-concentration organic wastewater (such as from food processing, alcohol distillation, pharmaceutical, etc.) has always been a major challenge in the wastewater treatment field. Plum Membrane’s Anaerobic Membrane Bioreactor (AnMBR) technology integrates anaerobic digestion processes with high-performance tubular membranes, achieving efficient COD removal and biogas recovery utilization. It not only significantly reduces wastewater treatment energy consumption but also generates green energy, truly realizing wastewater resource utilization and circular economy objectives.

Process Overview

The AnMBR solution combines an anaerobic bioreactor with an external tubular membrane separation system, achieving efficient organic matter degradation while ensuring stable and clear effluent quality. This system is particularly suitable for treating high-concentration organic wastewater in industries such as food, beverage, pharmaceutical, alcohol, and brewing, not only greatly reducing operational energy consumption and sludge production but also enabling biogas production and improving overall energy recovery efficiency. The modular design features a compact footprint, flexible operation, strong impact load resistance, and excellent operational stability.

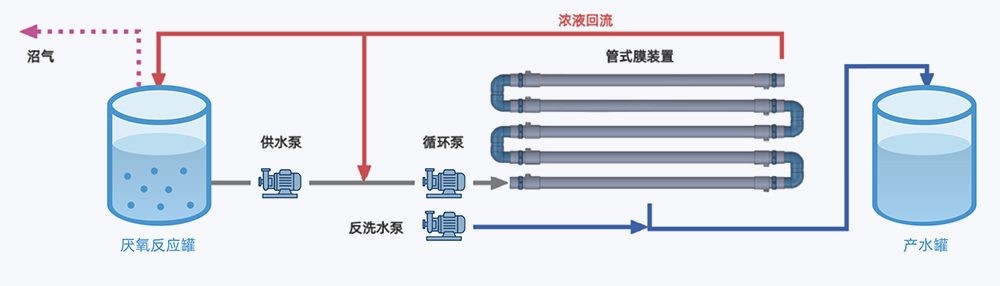

Process Flow

High-concentration organic wastewater first enters the anaerobic bioreactor, where under anaerobic conditions, anaerobic microorganisms degrade organic matter in the wastewater and produce recoverable biogas; the wastewater after biochemical treatment enters the anaerobic MBR membrane module for solid-liquid separation, further reducing COD, suspended solids, and large-molecule organic pollutants in the wastewater, with clear and stable produced water quality meeting subsequent discharge or deep treatment requirements. The separated concentrated sludge is circulated back to the anaerobic reactor, maintaining stable biomass in the reactor. The overall process system has a high degree of automation, low membrane fouling rate, simple operation and maintenance, effectively achieving energy recovery and resource recycling.

Process Highlights

Applications

Case Photos

Anaerobic MBR (AnMBR) Solution

Anaerobic MBR (AnMBR) Solution

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China