Introduction

Biopharmaceutical raw materials come from a wide range of sources, including natural origins such as microorganisms, plants, and animals, as well as biologically active substances produced through genetic engineering or synthetic biology techniques. These raw liquids typically contain important components like proteins, peptides, organic acids, and sugars, while also featuring complex impurities and high thermal sensitivity. Conventional extraction methods often suffer from low efficiency and insufficient purity. Plum Membrane Technology Co., Ltd. provides a high-flux, low-energy consumption process combining tubular membranes + ultrafiltration + nanofiltration/RO, meeting requirements for sterilization, impurity removal, decolorization, removal of pyrogenic gene fragments, and efficient concentration. It is suitable for continuous and aseptic processing of high-quality pharmaceutical fluids.

Background & Challenges

Process Flow

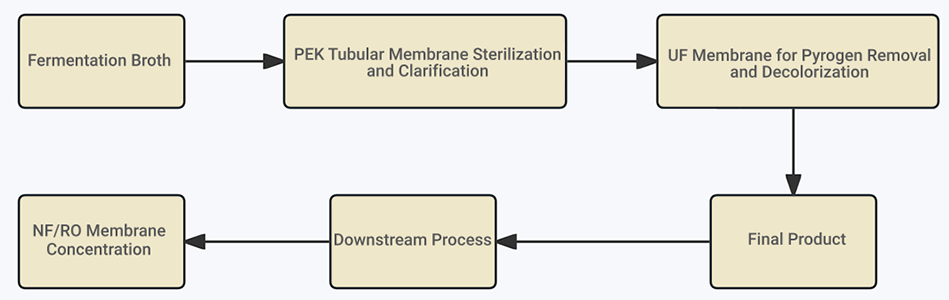

The biopharmaceutical membrane extraction and purification process primarily targets complex components in fermentation broths. It uses tubular membranes for efficient sterilization and impurity removal from the fermentation broth, eliminating suspended particles, bacterial residues, and other solid impurities. Subsequently, ultrafiltration membranes are employed for further decolorization, pyrogen removal, and improved liquid clarity. Then, nanofiltration or reverse osmosis membranes concentrate the target products, increasing active ingredient content and reducing subsequent energy consumption. Finally, this is combined with post-treatment processes such as resin adsorption, crystallization, and drying to obtain high-purity, high-activity biopharmaceutical-grade products. It is widely applied in high-value fields such as amino acids, antibiotics, organic acids, and peptides

Process Highlight

Applications

Case Photos

Nucleotide Membrane Separation Extraction Equipment

Pesticide Membrane Separation Equipment

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China