Introduction

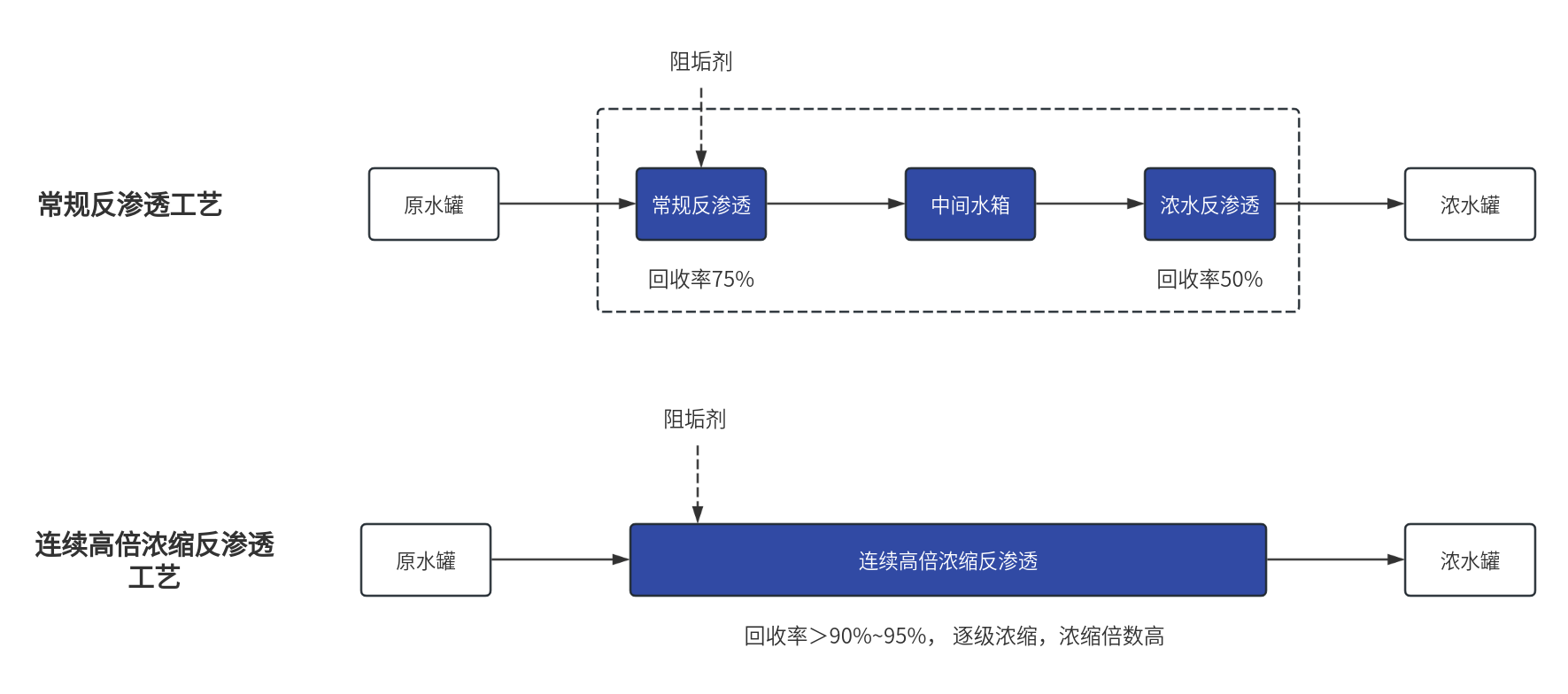

With rising demands for high recovery and deep concentration in industrial wastewater treatment, conventional RO systems—limited by their design—struggle to sustain long-term, stable, continuous operation. Plum Membrane’s independently developed High Recovery Continuous Concentration Reverse Osmosis (HRCC RO) technology uses modular architecture and advanced automation to deliver continuous, efficient concentration at >90% recovery, providing a reliable and economical pathway for resource utilization of high-salinity, high-strength wastewater.

Background & Challenges

To reach high recoveries, conventional RO concentration typically relies on multi-stage trains plus intermediate tanks and feed pumps, resulting in large footprints and complex systems. Frequent CIP shutdowns drive up O&M costs and manual dependence, making continuous, stable operation on high-salinity, high-TDS feeds difficult. A more efficient, lower-energy, highly automated concentration solution is needed.

Process Overview | Process Overview

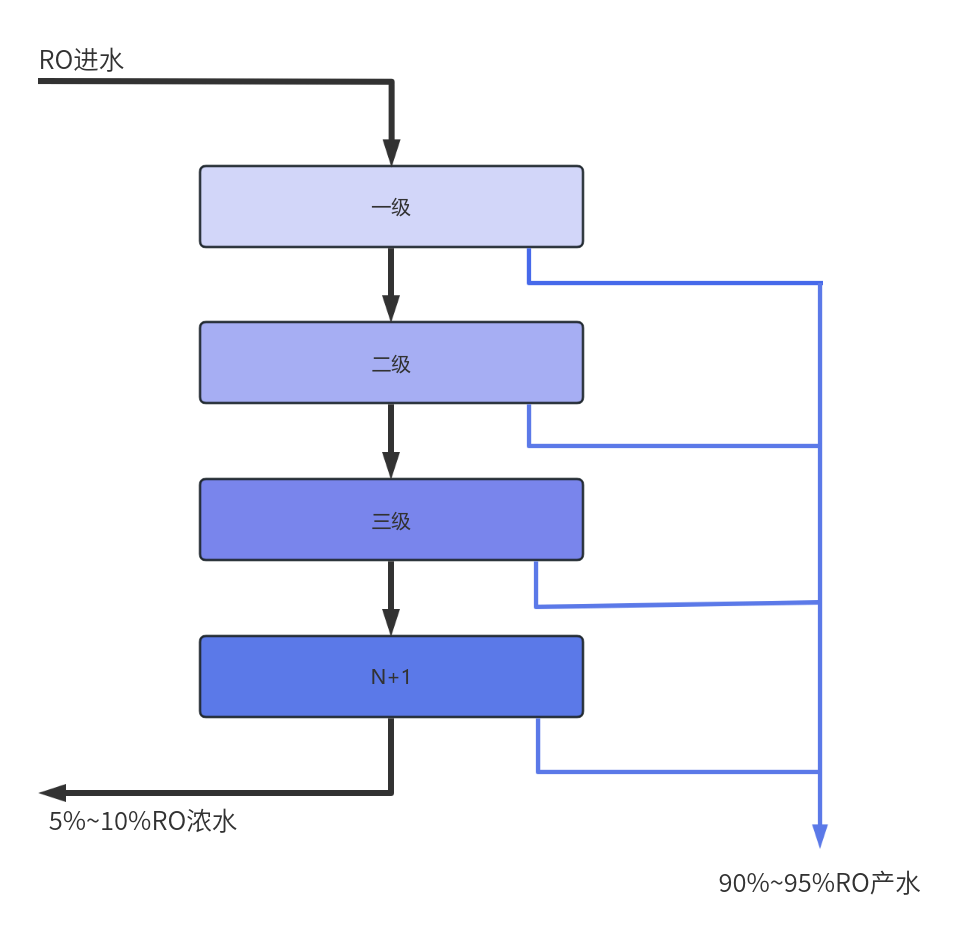

The HRCC process uses a modular N+1 configuration to achieve continuous operation and efficient concentration at 90–95% recovery. It automatically adjusts load to influent fluctuations and maintains production during CIP, enabling true 24/7 operation. Real-time monitoring and automated control optimize parameters to ensure stable product-water quality and concentration performance for high-salinity, high-strength feeds.

Process Flow Comparison

|

Item |

Conventional RO Process |

HRCC RO Process |

|

System Configuration Design |

2N grouping, manual switching; cleaning requires shutdown; multi-stage, complex layout |

N+1 automatic operation, auto membrane-group switching; no shutdown during CIP; fully modular and concise |

|

Single-System Recovery |

typically ≤75%; ≥90% requires an additional RO stage |

90–95% from a single train; simpler system |

|

Adaptability to Influent Fluctuations |

narrow control range; manual intervention required |

auto flow recognition with flexible load turndown/up across 30–120% |

|

Footprint |

multi-stage RO, intermediate tanks and feed pumps → large footprint |

compact layout; footprint reduced by ≈30–50% |

|

Continuous Operation Capability |

shutdown required for cleaning |

no production stoppage during CIP; 24/7 operation |

|

Automation Level |

cleaning and switchover rely on operators |

fully automatic operation/CIP/group switching/monitoring; no on-site intervention |

|

Cleaning Method & Effect |

manual cleaning; unstable dosing; membrane life impacted |

automatic dosing and full-flow CIP; controlled conditions; self-assessment of cleaning results |

|

O&M Costs |

high labor reliance, frequent maintenance, frequent membrane replacement |

high automation, low manpower, longer membrane life, lower overall costs |

|

Investment Costs |

complex system; higher CAPEX for trains/tanks/pumps |

slightly higher automation CAPEX, fewer components; overall CAPEX comparable |

|

Comprehensive Economic Benefits |

HRCC offers higher automation, stable operation, smaller footprint, and lower maintenance costs—superior long-term economics versus conventional RO. |

|

Process Flow

After pretreatment, feedwater enters the HRCC system. Multi-module series operation with dynamic switching enables high-ratio concentration and continuous permeate production. The system self-adjusts to flow fluctuations and maintains production during CIP. Concentrate is routed to subsequent treatment or resource recovery; permeate is reused or discharged to standards.

Process Highlights

Applications

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China