Introduction

Plant extract liquids contain various complex components, and conventional processes such as plate-and-frame filtration, filter machines, centrifugal filtration, and alcohol precipitation concentration exhibit significant drawbacks in sterilization, impurity removal, energy consumption, and product quality consistency. Plum Membrane Technology Co., Ltd. has developed a continuous membrane separation and concentration system with exceptional anti-fouling capabilities and cleaning characteristics. This system is suitable for impurity removal and concentration of permeable tea leaves, stevia, eucommia, and other plant extracts, as well as upgrades for vinegar and soy sauce fermentation products. It is particularly applicable for the extraction and purification of high-value components such as plant glycosides and flavonoids in sugar-free or oligosaccharide forms.

Background & Challenges

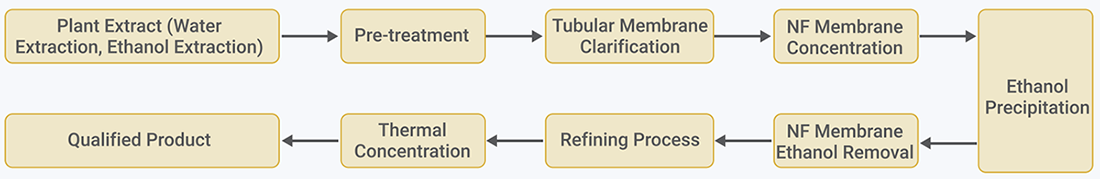

Process Flow

After pretreatment, the plant water extract or alcohol extract first undergoes efficient removal of suspended impurities and colloids through tubular membranes, ensuring stability for subsequent concentration and purification. Nanofiltration membranes are then applied for selective concentration to increase target active ingredient content, combined with nanofiltration desalination to effectively reduce salt and small-molecule impurity levels. Further solid-liquid separation is achieved through settling or centrifugation, followed by thermal concentration to reduce volume and enhance concentration. Finally, alcohol precipitation, nanofiltration dealcoholization, and refining processes yield high-purity products meeting quality standards, widely used in high-value fields such as plant extracts, natural products, and functional food ingredients.

Process Highlight

Applications

Case Photos

Cistanche Membrane Separation Extraction Equipment

Corn Cob Steam Explosion Extraction of Xylooligosaccharides "Full Membrane Method" Production Process

Chicory and Jerusalem Artichoke Extraction of Fructooligosaccharides "Full Membrane Method" Production Process

Traditional Chinese Medicine Extract Liquid Membrane Treatment Equipment

Hebei Scutellaria Extract Liquid Membrane Treatment Equipment

Tea Extract Liquid Membrane Treatment Equipment

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China