Introduction

The coal chemical industry generates large volumes of high-salinity, high-organic, and high-hardness wastewater during coal-to-liquid, coal-to-gas, and coal-to-olefin processes. Due to their complex composition and high pollution load, conventional treatment methods struggle to achieve discharge standards or enable resource recovery. Plum Membrane integrates PEK tubular membranes, nanofiltration-based salt separation, and HRCC high-recovery concentration to deliver a systematic zero liquid discharge (ZLD) solution that fulfills both environmental and water reuse needs.

Background & Challenges

Coal chemical wastewater poses several treatment challenges:

Typical Feed Water Characteristics

Process Flow

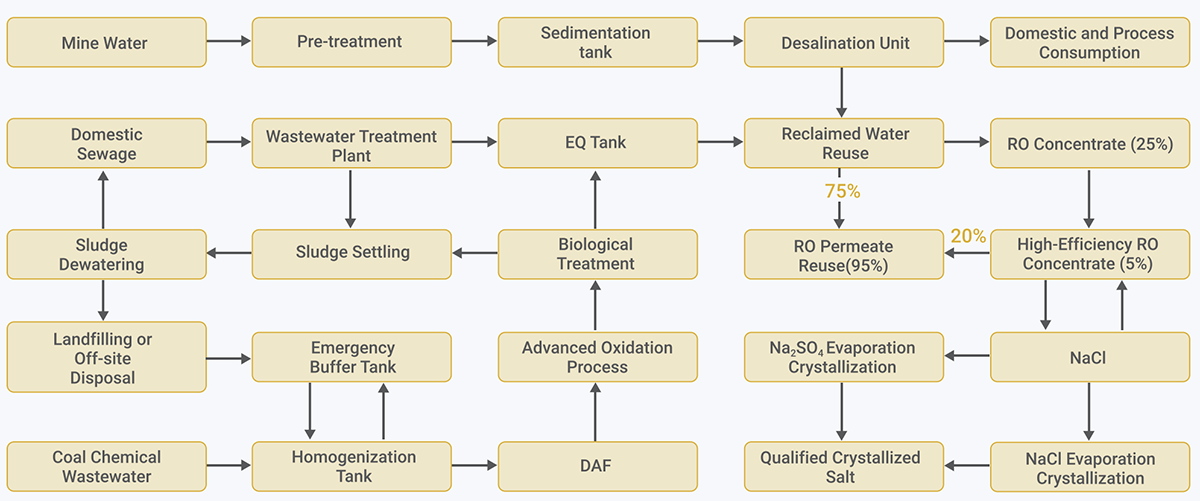

Coal chemical wastewater first undergoes pretreatment and purification to remove large suspended solids, colloids, and some organic matter, ensuring stable downstream operations. After pretreatment, the water enters the demineralization station for further purification, primarily used as process and domestic water. A portion of the product water also enters the water reuse station to serve as make-up water for the circulating cooling system, significantly reducing freshwater consumption. The reuse station operates with a 75% RO recovery rate. The remaining high-salinity wastewater and brine are sent to a secondary RO concentration unit, achieving an additional 25% recovery, allowing for a total water recovery rate of up to 95%. The remaining 5% is treated in a deep concentration system using high-efficiency reverse osmosis and nanofiltration to separate and purify salts. The resulting concentrated salt solution enters a high-efficiency evaporation and crystallization unit, where multiple-effect evaporation and cooling crystallization recover sodium chloride and other byproduct salts as marketable resources. The mother liquor generated is further treated for hardness, silica, fluoride, COD, and salt separation before being recycled or partially redirected to upstream treatment. Any remaining impurities are handled through solid waste treatment or external landfill disposal, ensuring full zero liquid discharge (ZLD). This process enables high-rate wastewater reuse and salt resource recovery in coal chemical operations, maximizing water utilization efficiency and minimizing environmental discharge, thereby supporting both environmental compliance and economic benefits.

Process Highlight

Alkaline softening combined with PEK tubular membranes effectively removes oils, organics, and hardness without coagulants, achieving final hardness <50 mg/L.

Efficient sulfate and chloride separation enhances water quality and reduces downstream load.

Single-stage RO recovery ≥90%, significantly reducing brine discharge.

Controls waste salt to <5%, enabling water and salt recovery.

Applications

Case Photos

Zero Liquid Discharge Process for Coal Chemical Wastewater

Zero Liquid Discharge Process for Coal Chemical Wastewater

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China