Introduction

Landfill leachate, characterized by high ammonia nitrogen, COD, heavy metals, and refractory organics, is considered one of the most challenging industrial wastewaters. With increasingly strict environmental standards, traditional processes struggle to achieve full-scale treatment and resource utilization. Plum Membrane has developed a nanofiltration-based full-scale solution integrating proprietary membrane systems and core technologies, enabling brine-free discharge, resource recovery, and compliant effluent.

Background & Challenges

Typical Feed Water Characteristics

Process Flow

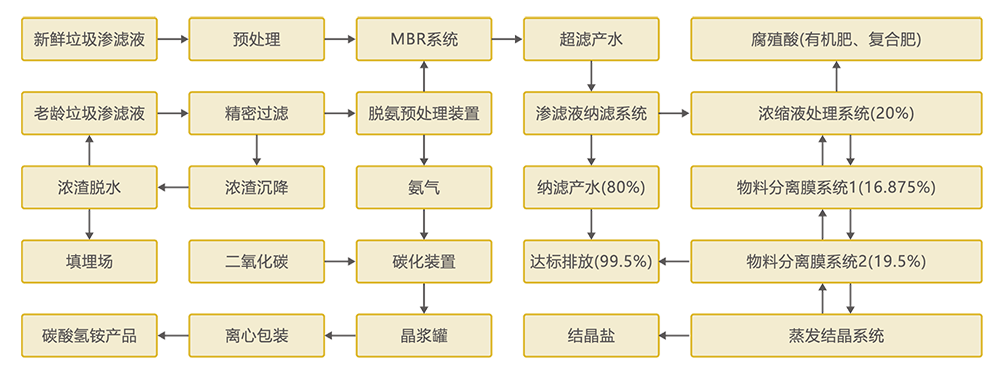

Fresh and aged landfill leachate first undergo separate pretreatment, precision filtration, and deammonification pretreatment units to remove large particulate suspended solids, colloids, ammonia nitrogen, and other pollutants, while adjusting the carbon-to-nitrogen ratio (6:1-10:1) to ensure stable water quality for subsequent systems. The water then enters the MBR system for further removal of organic matter and ammonia nitrogen, yielding high-quality ultrafiltrate that can be partially utilized for humic acid recovery (as organic or compound fertilizers). The MBR-treated leachate proceeds to the nanofiltration concentration system (80%), where the permeate is recycled internally, and the concentrate is divided into two streams entering the downstream membrane separation system (approximately 16.875% and 19.5%), enabling deep separation of salts and organics. Finally, it enters the evaporation crystallization system to produce high-purity crystalline salts, with the byproduct liquor processed through carbon dioxide and carbonization units to yield ammonium bicarbonate, which is centrifuged and packaged for use as a byproduct. The entire process achieves full quantitative closed-loop treatment of leachate without the need for high-pressure membrane processes such as RO or DTRO, eliminating high-salinity concentrate discharge, with a total system recovery rate exceeding 99.5%, maximizing resource recovery of water and salts, and truly attaining a "near-zero discharge" objective.

Design Influent and Effluent Water Quality

|

Treatment Unit |

Item |

COD (mg/L) |

BOD₅ (mg/L) |

NH₃-N (mg/L) |

TN (mg/L) |

SS (mg/L) |

NO₃-N (mg/L) |

|

3200 m³/d Leachate Treatment System |

Influent |

800–1000 |

20–30 |

≤10 |

40–50 |

≤2 |

20–30 |

|

640 m³/d Concentrate Treatment System |

Influent |

3500–4000 |

20–30 |

≤10 |

40–50 |

≤2 |

20–30 |

|

Discharge Standard |

Product Water |

40–60 |

20 |

≤8 |

≤20 |

0 |

15 |

Process Highlight

Case Photos

Landfill Leachate Treatment — All-Nanofiltration (NF) Process

Landfill Leachate Treatment — All-Nanofiltration (NF) Process

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China