Introduction

Addressing the challenges of conventional MBR processes, such as unstable operation and high energy consumption in systems with medium to low activated sludge concentrations (MLSS). Plum Membrane’s Air Lift MBR technology employs a unique gas-liquid mixed circulation method, enhancing shear force and mass transfer effects on the membrane surface, effectively reducing membrane fouling, maintaining stable membrane flux, and significantly lowering system energy consumption and operating costs. It is particularly suitable for wastewater treatment environments with low and highly fluctuating MLSS, offering enterprises an economically reliable membrane solution.

Process Overview

The Air Lift MBR employs gas elevation (Air Lift) technology, through the flow shear force generated by rising bubbles, enabling continuous circulation of water flow within the tubular membrane module, promoting thorough mixing of sludge and water, and efficient synergy of membrane separation. The system not only provides ample dissolved oxygen, enhancing microbial activity, but also effectively reduces membrane fouling and improves system operational stability.

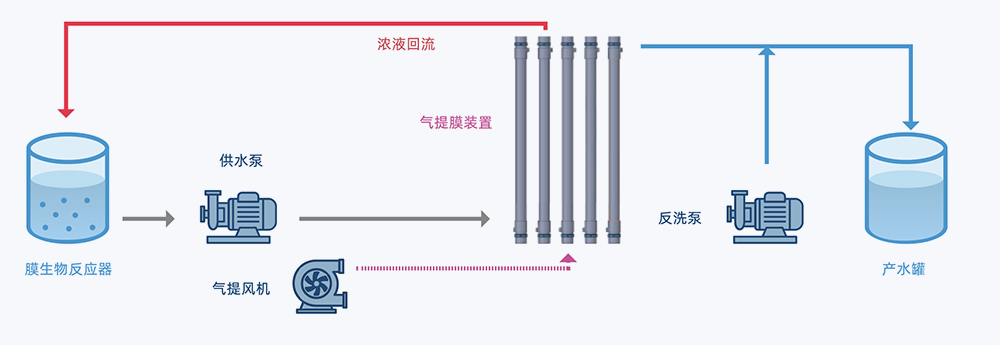

Process Flow

Wastewater enters the biological reaction tank, after degradation of organic matter by activated sludge, enters the Air Lift MBR membrane module. The system utilizes gas-liquid mixed elevation technology, through a dedicated gas elevation fan uniformly delivering air into the bottom of the membrane module, causing the wastewater to pass through the membrane surface at high speed in a gas-liquid mixed state, producing intense shear and disturbance effects, effectively preventing membrane fouling and sludge deposition. The permeate is filtered through the membrane module and enters the produced water tank for reuse or standard discharge, while the concentrate and sludge return to the biological reaction tank for continued cyclic treatment. The overall process design is sophisticated, with stable operational flux and low maintenance frequency, ensuring long-term stable high-efficiency processing capability.

Process Highlights

Applications

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China