Product Overview

Tubular membrane elements are high-strength components based on a tubular support with a membrane layer coated on the inner wall. They are suitable for processing water or fluids with high suspended solids, high viscosity, and high pollution loads. As the core product of Plum Membrane, PEK tubular membranes offer exceptional anti-fouling performance, superior acid and alkali resistance, and high mechanical strength. They are widely applied in industrial wastewater pretreatment, deep purification, and fluid membrane separation fields.

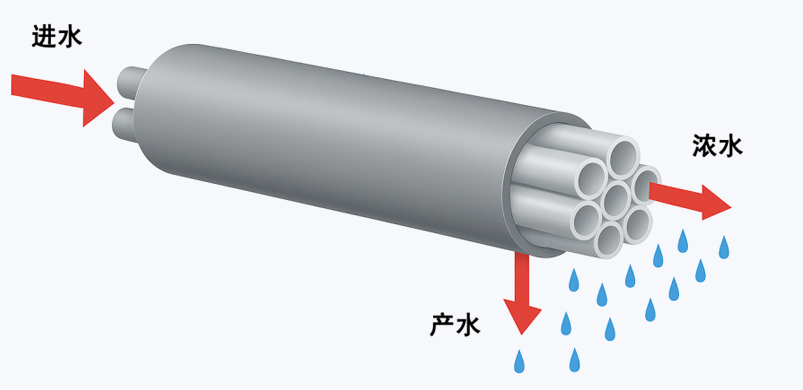

Working Principle

Adopting cross-flow filtration, the feed flows at high velocity inside the membrane tube, creating shear forces that effectively prevent contaminant deposition on the membrane surface. Water and small-molecule solutes pass through the membrane wall to form permeate, while suspended solids, oils, and large-molecule impurities are discharged at the concentrate end, ensuring continuous and stable separation.

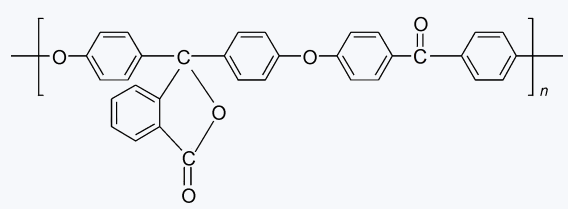

Core Technology: PEK

Polyetherketone (PEK) is a high-performance specialty engineering plastic successfully developed and industrialized in the 1980s. Its comprehensive performance is comparable to that of PEEK; due to its main chain containing ketone groups and numerous ether bonds, it exhibits outstanding mechanical properties, chemical stability, and high-temperature resistance. It is widely applied in high-end manufacturing fields such as aerospace, energy industry, transportation, and electronic information.

We use PEK material to manufacture tubular membranes that withstand chemically aggressive, highly concentrated, and heavily polluted fluids. Compared to conventional PVDF tubular membranes, PEK membranes deliver greater durability, superior fouling resistance, and easier cleaning, making them a more reliable choice for high-efficiency separation and filtration.

High thermal resistance: Glass transition temperature (Tg) up to 230°C

Superior mechanical strength: Tensile strength 102 MPa, flexural strength 132 MPa

Excellent acid and alkali resistance: Resistant to 50% H₂SO₄, 38% HCl, 30% HNO₃, 20% HF, and 30% NaOH

High chlorine tolerance: Stable under 10% sodium hypochlorite

Membrane Performance Parameters

| Index | Unit | PEK | |||||

| PVDF | PEK | PEK (Composite Support Layer) | PK | ||||

| Pore Size / MWCO | / | 30nm | 0.2um | 50nm | 10nm | 30nm | 0.1um |

| Pure Water Flux | LMH/100kPa | 900 | 2000 | 1200 | 300 | 1000 | 1500 |

| Operating Pressure | kPa | -50~800 | -100~1000 | -50~800 | -100~1000 | ||

| Max Operating Temperature | ℃ | 60 | 60 | 50 | 50 | ||

| pH Operating Range | / | 2~10 | 0~12.5 | 0~14 | 1 ~ 11 | ||

| Oxidation Resistance | ppm·h | 250000 | 300000 | 300000 | 200000 | ||

Key Performance Advantages

Applications

Membrane Module Photos

Membrane Element Photos

Membrane Element Photos

Membrane Element Photos

Membrane Element Photos

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China