Introduction

Salt lakes and mineral ores are currently the two main lithium resources. Salt lake brines typically exhibit low lithium concentrations, very high magnesium-to-lithium ratios, and numerous impurities, whereas ore-derived lithium extraction solutions contain high concentrations of sulfate and complex salts. Addressing the difficulty in selective lithium extraction and handling of byproduct streams, Plum Membrane developed a membrane-based lithium recovery approach utilizing membrane integration, adsorption, salt separation, and concentration technologies, delivering an environmentally friendly, continuous, and high-recovery process.

Background & Challenges

Typical Feed Water Characteristics

Mineral Ore Extraction:

Salt Lake Extraction:

Process Flow

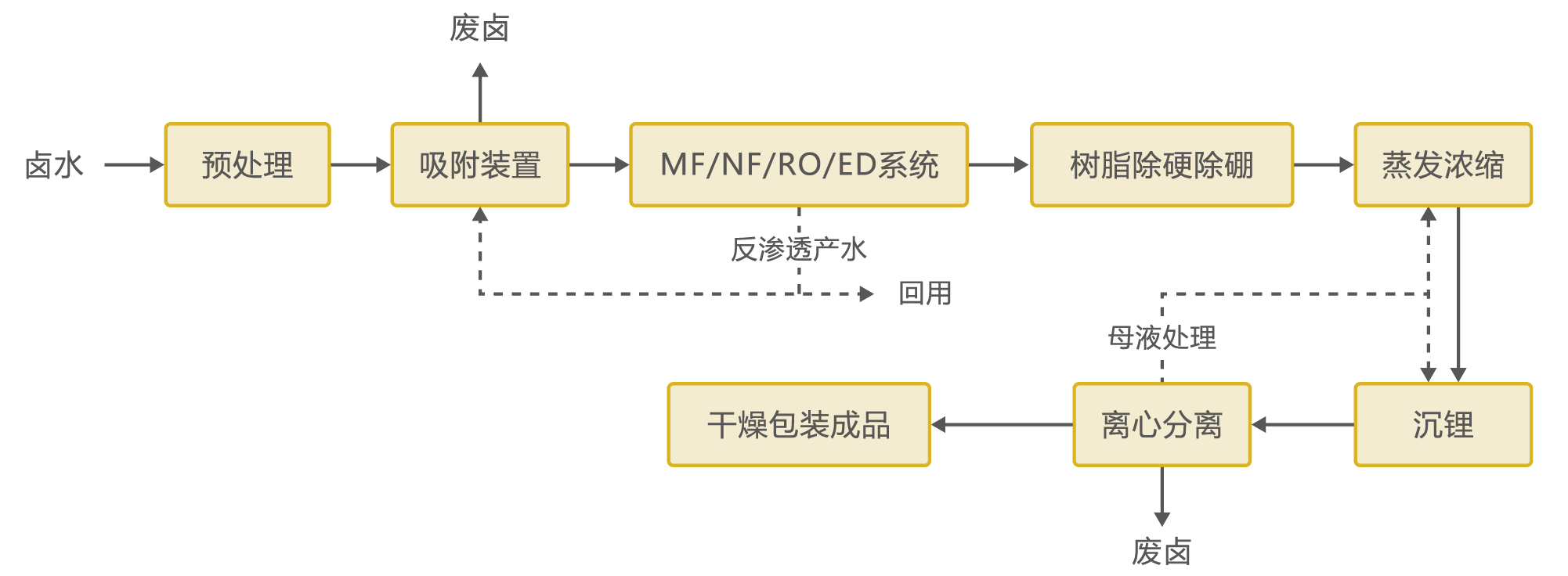

The lithium extraction process is flexibly configured according to salt lake or mineral ore pathways, covering the entire process from pretreatment to product crystallization. Initially, clarification and PEK tubular microfiltration efficiently remove suspended solids and colloids, protecting downstream operations. Highly selective adsorbents then remove interfering ions such as magnesium and aluminum. Subsequently, multi-stage membrane systems (MF/NF/RO/ED) achieve precise separation of monovalent and divalent ions, enriching lithium ions. Further resin softening and evaporation concentration enhance lithium content, and lithium chloride or lithium carbonate is produced through precipitation or crystallization. Residual brine undergoes salt separation, enabling secondary salt resource recovery or compliant discharge. The integrated process is adaptable, precise, and resource-efficient, suitable for various lithium resource development scenarios.

Process Highlight

Applications

Case Photos

Lithium Extraction and Resource Recovery from Salt Lakes and Ores Using Membrane Processes

Lithium Extraction and Resource Recovery from Salt Lakes and Ores Using Membrane Processes

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China