Introduction

Mine water (underground drainage water) often contains high concentrations of suspended solids, hardness, heavy metals, salts, oils, and soluble organic substances, making it a challenging wastewater type to treat. To effectively address mine water characteristics, Plum Membrane has developed an integrated solution involving pretreatment systems, PEK tubular membranes, two-stage nanofiltration, and HRCC high-recovery concentration technology. This solution enables significant volume reduction, precise salt separation, and resource recovery, helping the mining industry achieve zero liquid discharge objectives.

Background & Challenges

Mine water from coal, non-ferrous metal, non-metallic mines, and integrated mining areas poses significant treatment challenges, as conventional methods struggle to meet discharge and reuse standards, primarily due to:

Typical Feed Water Characteristics

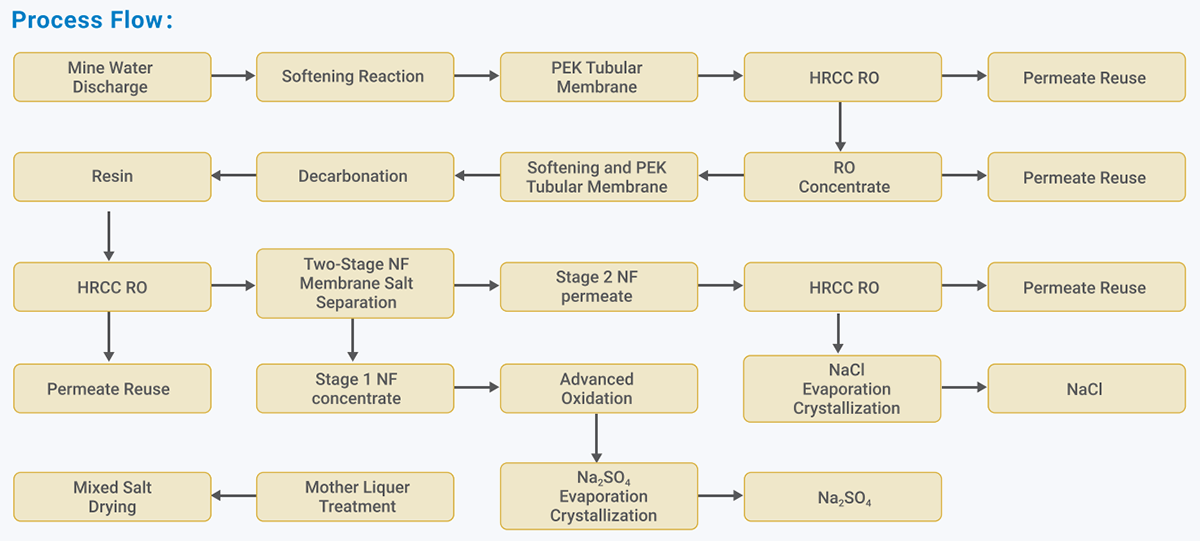

Process Flow

Pretreated mine water (underground drainage) first undergoes softening reactions with alkali dosing to remove hardness ions, followed by cross-flow filtration in a PEK tubular membrane unit to effectively remove residual suspended solids and fine particulates. The permeate can be directly reused, while the concentrate proceeds to further treatment. For high-salinity and high-hardness concentrate, it undergoes decarbonation and resin softening, followed by additional softening and silica removal in another PEK membrane system, significantly reducing hardness and silica levels. Subsequently, reverse osmosis (RO) produces high-quality permeate suitable for comprehensive reuse. Multi-stage nanofiltration (NF) and RO units then precisely separate and concentrate various salts. Through successive NF and RO stages, streams with different salt compositions are extracted and separated. The concentrated solutions enter chlorine oxidation and sodium chloride evaporation crystallization units, yielding high-purity refined sodium chloride. Mixed-salt mother liquors are processed by evaporation crystallization systems, producing sodium sulfate as a valuable byproduct, with solid waste undergoing drying.

Process Highlight

The Plum Membrane ZLD solution for mine water incorporates several core technologies:

Combines softening with PEK tubular membrane filtration, replacing traditional sedimentation and sand filtration processes. Achieves hardness levels below 50 mg/L and total silica below 10 mg/L without additional coagulation/flocculation chemicals.

Features a recovery system limiting mixed salt formation to below 5%, enhancing resource recovery and reducing subsequent treatment burdens.

NF concentrate maintains a sulfate-to-chloride mass ratio above 10:1, and NF permeate features a chloride-to-sulfate mass ratio exceeding 60:1, ensuring effective separation of monovalent and divalent salts while enhancing permeate quality.

Employs HRCC technology to achieve single-stage RO recovery rates of ≥90%, significantly increasing overall concentration and reducing effluent volumes.

Applications

Case Photos

Zero Liquid Discharge (ZLD) Process for Mine Water

Zero Liquid Discharge (ZLD) Process for Mine Water

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China