Introduction

Conventional MBR systems, when handling high-concentration or complex wastewater, often face severe membrane fouling, reduced operational flux, and frequent cleaning and maintenance challenges. Plum Membrane’s Cross Flow MBR system, developed based on cross-flow technology, significantly improves membrane filtration flux and anti-pollution performance, ensuring long-term stable operation of the membrane module under high MLSS environments, greatly reducing operation and maintenance costs, and is especially suitable for difficult-to-treat wastewater such as high suspended solids, high oil content, high organic loads, helping enterprises achieve efficient and stable wastewater resource utilization.

Process Overview

The external MBR solution adopts a combination form of "front-end biochemical tank + tubular membrane external filtration unit", integrating high-load organic pollutant biological degradation capability with high-flux cross-flow membrane separation technology, specifically designed for complex organic wastewater treatment. The system features strong anti-pollution capability, long operational cycles, simple maintenance, and is particularly suitable for treating high-concentration wastewater containing oil, suspended solids, high COD/BOD, etc.

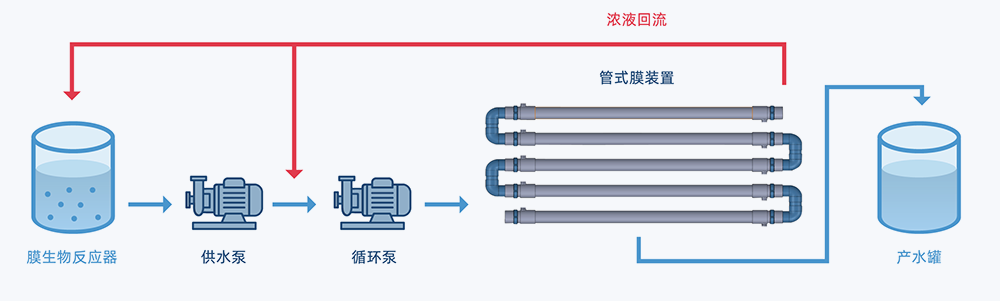

Process Flow

Wastewater first enters the biological reaction tank, through the biochemical action of activated sludge effectively degrading organic pollutants, then enters the cross-flow MBR membrane system for solid-liquid separation. The membrane system adopts cross-flow filtration method, with high-speed circulating fluid forming strong shear force on the membrane surface, effectively inhibiting deposition of sludge particles and membrane fouling, stabilizing membrane flux. The separated clear permeate directly enters the produced water tank for subsequent reuse or discharge; the membrane concentrate is circulated back to the biological reaction tank, continuously maintaining higher sludge concentration, ensuring efficient and stable wastewater treatment effect. The entire process is fully automated, simple to maintain, guaranteeing long-term stable operation.

Process Highlights

Applications

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China