Introduction

In sugar production processes, large amounts of low-concentration dilute rare sugar solutions (5–8%) are often generated. Direct evaporation concentration leads to high energy consumption and substantial operating costs. Plum Membrane Technology Co., Ltd. employs multi-stage membrane concentration coupled with back-end evaporation technology to elevate the concentration of dilute rare sugar solutions from 5–8% to 20–35%, significantly reducing steam consumption and wastewater discharge. The membrane separation process is mild, without phase changes, effectively preserving active substances in the sugar solution, improving system yield, and supporting green production and circular utilization goals.

Background & Challenges

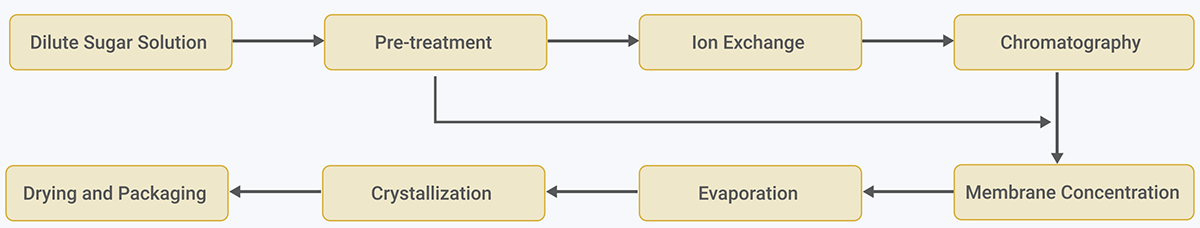

Process Flow

The dilute rare sugar solution first undergoes pretreatment to remove suspended impurities, colloids, and large particles, ensuring the stability of subsequent membrane and separation processes. It then proceeds through ion exchange to eliminate inorganic salts and charged small-molecule impurities, further enhancing purity. Next, chromatographic processes perform fine separation and purification of target sugars, improving product color and flavor. Part of the liquid stream can be directly returned to the membrane concentration stage for concentration and purification, increasing sugar solution concentration and reducing energy consumption. The membrane-concentrated sugar solution then undergoes further evaporation for high-purity sugar enrichment. Finally, the concentrate enters the crystallization stage to form crystalline sugars, followed by drying and packaging to produce high-purity products meeting food or functional ingredient standards, achieving efficient recovery of dilute rare sugar solutions and resource utilization of wastewater.

Process Highlight

Applications

Case Photos

45m³/h Maltitol Concentration System

5m³/h Allulose and Glucose Concentration System

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China