Introduction

Oily wastewater is prevalent in petrochemical, oilfield, mechanical processing, food, and other industries, often containing high levels of free oil, emulsified oil, and suspended solids, posing significant treatment challenges and strict processing requirements. Conventional processes typically require complex multi-stage gravity separation, flotation, and sand filtration, but still fail to ensure stable compliance. Based on years of engineering expertise, Plum Membrane has independently developed a tubular membrane oil removal solution, with superior oil resistance, anti-pollution properties, and high-flux operation, achieving efficient oil and impurity removal, stable effluent quality, meeting reuse or discharge standards.

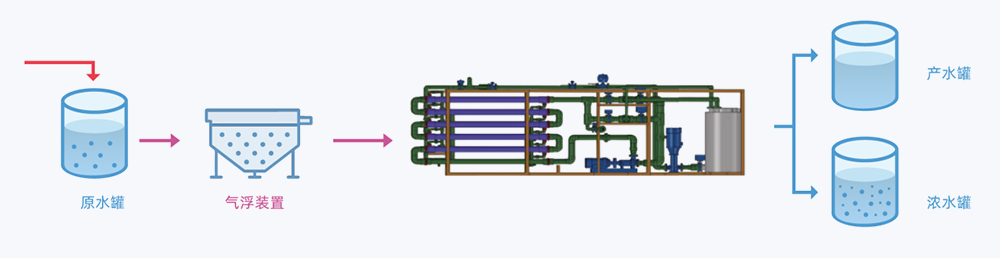

Process Overview

This solution features high-strength, pollution-resistant PEK tubular membranes as the core, combined with front-end physicochemical pretreatment, effectively removing free oil, emulsified oil, and large-particle suspended solids, with produced water oil content stably controlled below 5 mg/L, oil removal rate up to 99% or more. The system employs cross-flow filtration principle, continuously reducing membrane surface pollution, maintaining high-flux long-term operation, high automation, simple maintenance, small footprint, especially suitable for complex wastewater treatment scenarios with high oil content and high pollution load fluctuations.

Process Flow

Oily wastewater first enters a buffer tank for flow and quality equalization, then proceeds to pretreatment units (e.g., dissolved air flotation or coarse filtration) to remove suspended oil. The pretreated water is then fed into the PEK tubular membrane system, where cross-flow filtration efficiently retains emulsified oil, dissolved oil, suspended oil, and solids. Permeate oil content is reduced to below 5 mg/L, meeting discharge or reuse standards. The membrane concentrate flows to sludge thickening and dewatering units, generating dewatered sludge cakes for off-site disposal. Filtrate is recycled to the buffer tank. The system is highly automated, supports continuous stable operation, and reduces labor and O&M costs.

Inlet and Outlet Water Parameter Comparison

|

|

Oil Content (mg/L) |

Suspended Solids (mg/L) |

Median Particle Size (µm) |

Sulfate-Reducing Bacteria (cells/mL) |

Corrosion Bacteria (cells/mL) |

Iron Bacteria (cells/mL) |

|

Inlet Water Quality |

<1000 |

<1000 |

<20 |

<1000 |

<10000 |

<10000 |

|

Outlet Water Quality |

<5 |

<1 |

<1 |

<10 |

<100 |

<100 |

|

Removal Rate |

99.5% |

99.9% |

- |

99% |

99% |

99% |

Process Highlights

Applications

Case Photos

Advanced treatment of oilfield produced water

Oilfield produced water treatment

Fracturing flowback fluid treatment

Produced water treatment at oil extraction site

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China