Introduction

In recirculating cooling systems, blowdown water often accumulates high levels of hardness, silica, dissolved salts, and organic contaminants due to continuous concentration, making reuse challenging. To improve water resource efficiency and reduce discharge burdens, Plum Membrane developed a blowdown treatment solution leveraging PEK tubular membrane technology and High-Recovery Cross-flow Concentration (HRCC). This solution significantly decreases blowdown discharge, enables efficient and stable reuse, and provides robust support for enterprises striving towards near-zero liquid discharge goals.

Background & Challenges

Industries such as petrochemical, power generation, and coal chemical frequently face the accumulation of hardness, silica, salts, and organic contaminants in cooling tower systems. Periodic blowdown is required to maintain water quality, resulting in large volumes of highly contaminated blowdown water. Traditional methods such as sedimentation and sand filtration have limitations, including:

Typical Feed Water Characteristics

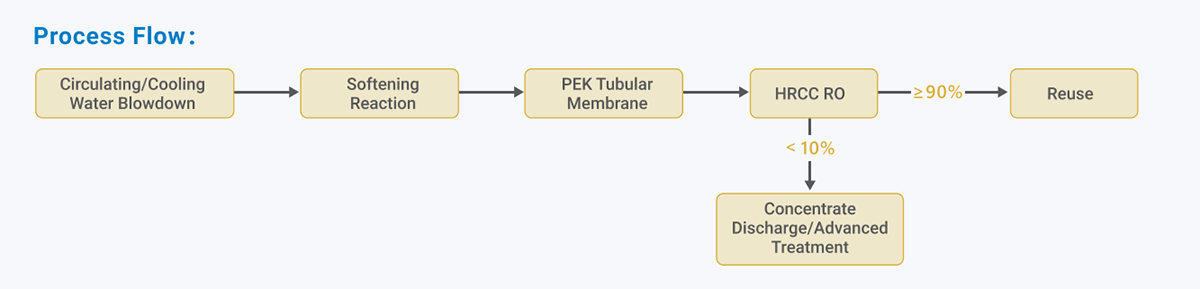

Process Flow

Under high-pH conditions, blowdown water undergoes softening reactions to convert hardness ions (Ca²⁺, Mg²⁺) and silica into suspended solids. These solids and impurities are then efficiently removed via PEK tubular membrane cross-flow filtration. The filtrate is further treated using HRCC high-recovery concentration technology for reuse, achieving overall water recovery rates above 90%. Only a small volume of concentrate requires subsequent handling. This process effectively addresses the scaling and reuse challenges posed by high-hardness and high-silica blowdown water.

Process Highlight

This integrated solution employing PEK tubular membrane technology, HRCC concentration, and automated controls achieves significant reduction and efficient reuse of cooling tower blowdown water:

Applications

Case Photos

Cooling Tower Blowdown Reduction and Reuse Process

Cooling Tower Blowdown Reduction and Reuse Process

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China