Introduction

Amid the continuous rise in global obesity rates, developing natural and healthy rare sugars as alternatives to traditional sweeteners has become a research hotspot. D-Allulose, with its low calorie content (approximately 0.3% of sucrose), high sweetness (about 70% of sucrose), and various biological activities (such as blood sugar reduction, weight control, and antioxidation), has garnered significant attention and has received safety certification from the U.S. FDA. Utilizing D-allulose 3-epimerase (DPE) to isomerize D-fructose is currently the most economical and environmentally friendly production method, requiring multiple purification steps such as decolorization and ion exchange to obtain high-quality products. To improve separation efficiency and purity, Plum Membrane Technology Co., Ltd. employs an "ultrafiltration + nanofiltration" membrane separation process, efficiently removing proteins, pigments, and polysaccharide impurities, simplifying the workflow, enhancing recovery rates, and meeting the demands for industrialized continuous production.

Background & Challenges

Process Flow

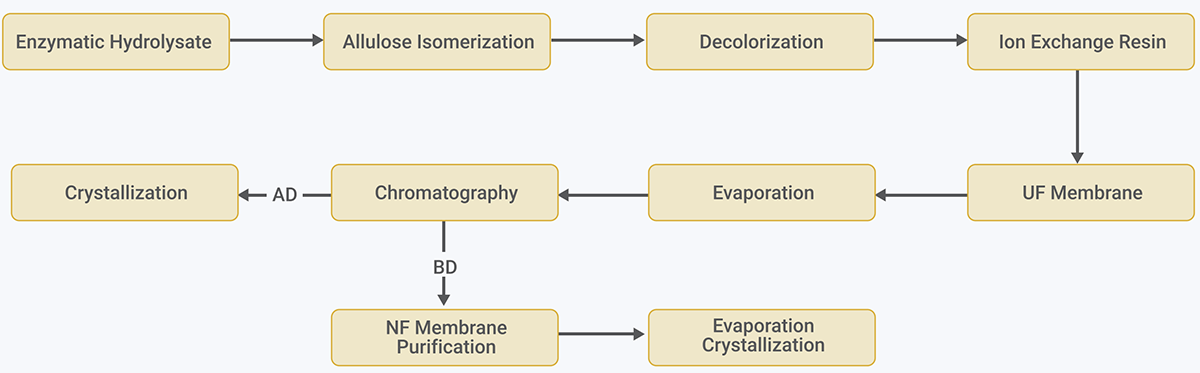

The fermentation broth first undergoes allulose isomerization to convert part of the fructose into allulose, followed by decolorization to remove pigments and phenols, enhancing the liquid's purity and sensory quality. Next, ion exchange removes residual impurities and salts, and ultrafiltration membrane separation further eliminates high-molecular-weight impurities and colloids, ensuring stability in subsequent concentration and crystallization stages. After evaporation concentration to increase allulose content, part of the solution directly enters chromatographic refining, while another portion undergoes nanofiltration purification to further remove small-molecule impurities before entering evaporation crystallization, ultimately yielding high-purity allulose crystalline products that meet high-quality demands for food, health supplements, and functional ingredients.

Process Highlight

Applications

Case Photos

Allulose Ultrafiltration Separation Equipment

Allulose Ultrafiltration Separation Equipment

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China