Introduction

Reusing reclaimed water is a key measure for water-saving and emission reduction in industrial parks. However, as RO systems become widespread, the high-salinity, high-hardness brine produced poses new challenges. Plum Membrane offers an integrated solution combining pretreatment, nanofiltration (NF) for salt separation, HRCC concentration, and mother liquor recovery, achieving both stable RO operation and near-zero liquid discharge.

Background & Challenges

RO systems are commonly used for reclaimed water reuse in industrial parks, but they face the following challenges:

Typical Feed Water Characteristics

Process Flow

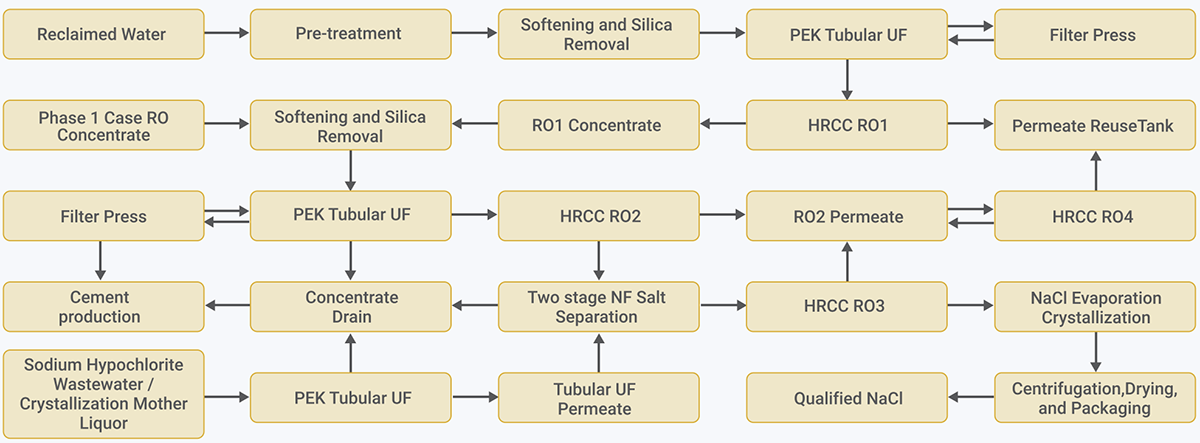

Reclaimed municipal or industrial park water first undergoes pretreatment and softening to remove part of the hardness and silica. The pretreated water then enters the PEK tubular membrane unit, where cross-flow filtration further removes suspended solids, hardness, and silica to prevent fouling in downstream membranes and ensure stable RO operation. The RO system is arranged in multiple stages: concentrate from the first-stage RO (RO1) is partially reused in a circulation tank, while some of it is softened again and fed into RO2. The remaining concentrate proceeds to RO3 and RO4 to maximize water recovery. The brine from all RO stages is collected and further concentrated and separated by the PEK tubular membrane concentration unit and nanofiltration system, achieving effective salt separation and purification. The separated high-salinity stream enters a sodium chloride evaporation and crystallization unit to produce high-purity NaCl. The by-product filtrate and mother liquor are further concentrated, softened, filtered through PEK membranes, and undergo nanofiltration again. The NF permeate is concentrated by RO and recycled to the crystallization frontend. A small amount of NF concentrate is terminally treated (e.g., incorporated into cement production with calcium carbide slag or desulfurization/denitrification systems). The final salt products undergo dewatering, drying, and packaging, meeting resource utilization requirements. The system achieves high reclaimed water reuse rates and near-zero RO brine discharge, significantly improving water resource efficiency and reducing environmental load.

Process Highlight

RO brine is reduced to < 50 mg/L (Ca²⁺, Mg²⁺ < 10 mg/L; SiO₂ < 10 mg/L), effectively reducing scaling risks for downstream systems.

The NF permeate has a Cl/SO₄²⁻ ratio > 60:1, enabling production of high-purity NaCl (≥ 98.5%), while the concentrate side achieves a SO₄²⁻/Cl⁻ ratio > 10:1, yielding high-purity Na₂SO₄ (≥ 99%).

HRCC design achieves ≥ 90% single-pass recovery. The system dynamically adapts to 30–120% flow variation.

The system recovers crystallization mother liquor with impurity salt content ≤ 5%, enhancing resource recovery and minimizing discharge.

The system adopts an “N+1” configuration, supporting 24/7 operation with online monitoring. Membrane cleaning does not interrupt water production, enabling up to 8400 hours of annual runtime.

Applications

Case Photos

Reclaimed Water Reuse & RO Brine Zero Liquid Discharge Process

Reclaimed Water Reuse & RO Brine Zero Liquid Discharge Process

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China