Introduction

Conventional plate-and-frame filtration, diatomaceous earth filters, hollow fiber, or ceramic membranes encounter issues such as insufficient clarification, short equipment lifespan, and high labor intensity when processing high-viscosity seasoning liquids (such as soy sauce and vinegar). Plum Membrane Technology Co., Ltd. has developed a fully automated ultrafiltration membrane system with advantages in high anti-fouling performance, strong impurity removal, and continuous operation. It achieves nearly 100% retention of suspended solids while allowing the permeation of small-molecule amino acids, organic acids, amino nitrogen, and other flavor components, ensuring the condiments remain clear and transparent with unchanged flavor and long-term stable operation.

Background & Challenges

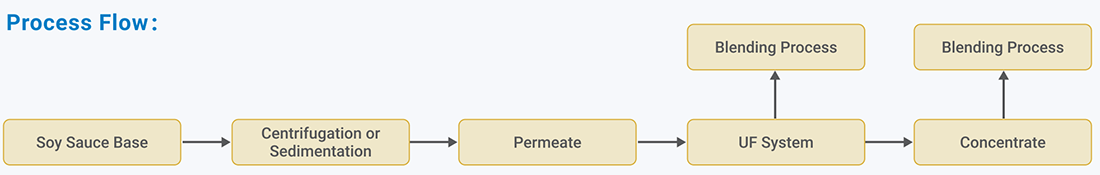

Process Flow

After preliminary removal of larger suspended particles and impurities through centrifuge pre-sedimentation and fine sedimentation, the condiment raw liquid enters the ultrafiltration membrane system for deep clarification. This effectively retains fine particles, colloids, and high-molecular-weight impurities, significantly improving product transparency and stability. The clarified liquid can directly proceed to blending processes for finished product preparation, while the concentrate produced by the ultrafiltration system can be further used for blending or recovery. The overall process is concise and efficient, enhancing product quality and optimizing production costs. It is widely applicable for deep purification and quality improvement in various condiments such as soy sauce, vinegar, and cooking wine.

Process Highlight

Applications

Case Photos

Sterilization and Impurity Removal Membrane Separation Projects Phases 1-5 at a Major Chinese Soy Sauce Company

Sterilization and Impurity Removal Membrane Separation Projects Phases 1-5 at a Major Chinese Soy Sauce Company

Sterilization and Impurity Removal Membrane Separation Projects Phases 1-5 at a Major Chinese Soy Sauce Company

Sterilization and Impurity Removal Membrane Separation Projects Phases 1-5 at a Major Chinese Soy Sauce Company

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China