Introduction

Lactic acid fermentation broth often suffers from deep color, numerous impurities, and residual sugars, which affect the purity and stability of end products. Conventional processes face challenges such as low recovery rates, high operating costs, and rapid membrane fouling when handling high-concentration lactic acid solutions. Plum Membrane Technology has developed a specialized nanofiltration system for lactic acid, incorporating secondary fine separation technology. This system enables stable operation at lactic acid concentrations of 40-50%, balancing impurity removal, decolorization, and high-purity recovery. It is suitable for efficient purification of food-grade and pharmaceutical-grade lactic acid, significantly improving economic efficiency for clients.

Background & Challenges

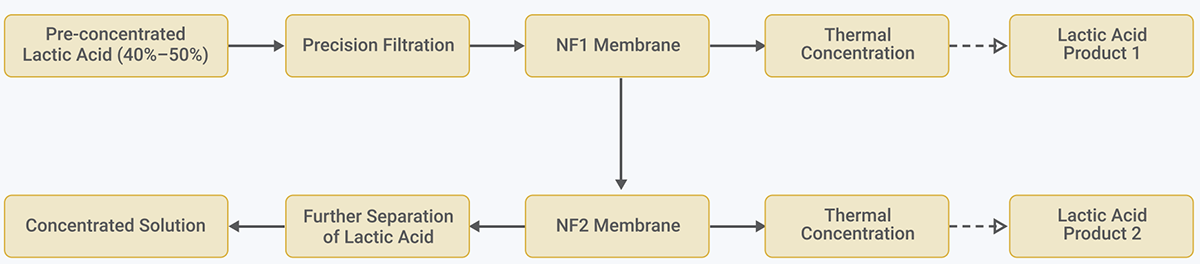

Process Flow

Pre-concentrated lactic acid solution (content 40–50%) first undergoes precision filtration to remove suspended impurities and colloidal particles, ensuring the stability of subsequent membrane processes. It then enters the primary nanofiltration system for initial decolorization and impurity removal, effectively eliminating polyphenols, pigments, residual sugars, and small-molecule impurities. The permeate undergoes further thermal concentration to increase lactic acid content, yielding high-purity lactic acid product 1. The primary nanofiltration concentrate proceeds to the secondary nanofiltration system for deep separation, further removing impurities and pigments, followed by thermal concentration to produce another high-purity lactic acid product 2. Through this graded nanofiltration combined with thermal concentration process path, efficient purification, resource utilization, and multi-product graded output of lactic acid are achieved, meeting quality requirements for various application fields.

Process Highlight

Applications

Case Photos

100,000 Tons/Year Lactic Acid Nanofiltration Membrane Project

50,000 Tons/Year Lactic Acid Nanofiltration Membrane Project

50,000 Tons/Year Lactic Acid Nanofiltration Equipment

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China