Introduction

The tubular membrane heavy metal removal solution combines front-end chemical reaction with high-strength PEK tubular membrane cross-flow filtration technology, specially designed for high-concentration, complex systems of heavy metal wastewater. The front-end achieves efficient precipitation of metal ions through precise dosing adjustment, and the back-end uses tubular membranes for efficient solid-liquid separation, with produced water heavy metal concentration stably reduced to extremely low levels, meeting rigorous discharge or reuse requirements. Compared to conventional chemical precipitation + multi-stage filtration combinations, the process is more compact, with smaller footprint, higher automation, simpler maintenance, and significant overall economic advantages.

Process Overview

Wastewater first enters the reaction tank, adding alkaline agents (such as sodium hydroxide) and auxiliary precipitants, adjusting pH to the appropriate range (usually 9~11), prompting heavy metal ions such as copper, nickel, lead, zinc in the wastewater to precipitate as hydroxides; subsequently, the precipitated wastewater directly enters the PEK tubular membrane system, adopting cross-flow filtration to efficiently retain and separate sludge, with produced water heavy metal concentration reduced to below 0.1 mg/L, meeting discharge or reuse standards. The membrane concentrate portion enters the sludge concentration and dewatering system, ultimately achieving sludge volume reduction for off-site transport, with de-sludging filtrate returned to the front-end reaction tank. The entire system can operate continuously and stably, with simple maintenance and excellent economy.

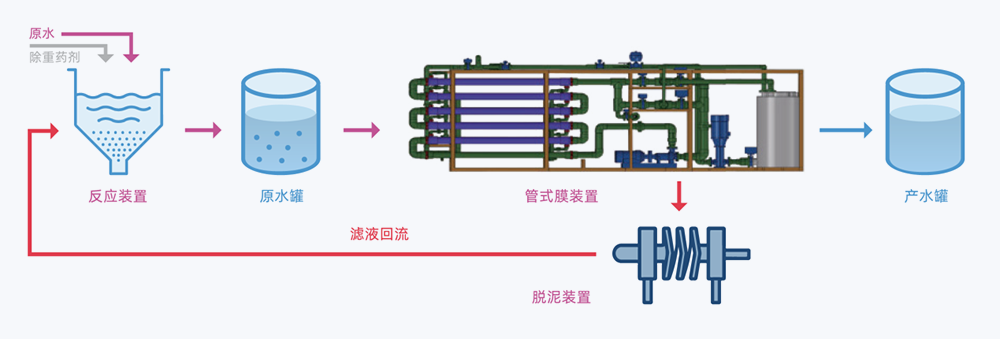

Process Flow

Wastewater first enters the reaction tank, adding alkaline agents (such as sodium hydroxide) and auxiliary precipitants, adjusting pH to the appropriate range (usually 9~11), prompting heavy metal ions such as copper, nickel, lead, zinc in the wastewater to precipitate as hydroxides; subsequently, the precipitated wastewater directly enters the PEK tubular membrane system, adopting cross-flow filtration to efficiently retain and separate sludge, with produced water heavy metal concentration reduced to below 0.1 mg/L, meeting discharge or reuse standards. The membrane concentrate portion enters the sludge concentration and dewatering system, ultimately achieving sludge volume reduction for off-site transport, with de-sludging filtrate returned to the front-end reaction tank. The entire system can operate continuously and stably, with simple maintenance and excellent economy.

Process Highlights

Applications

Case Photos

Copper removal from PCB manufacturing wastewater

Aluminum removal from casting industry process water

Iron removal from alkaline washing wastewater in steel industry

Iron removal from pickling wastewater in steel industry

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China