Introduction

Conventional chemical softening processes are cumbersome, occupy large areas, require high chemical dosages, and have limited effectiveness for wastewater with high hardness and high silica content. Plum Membrane’s independently developed PEK softening process package integrates advanced PEK tubular membrane technology, achieving deep removal of hardness, silica, and certain heavy metals via high-pH softening reactions combined with cross-flow filtration. Featuring a short process flow, small footprint, high automation level, and low chemical consumption, it is particularly suitable for pretreating complex systems such as circulating cooling blowdown water and industrial high-hardness wastewater, ensuring long-term stable operation of subsequent NF/RO systems.

Process Overview

The PEK softening process solution employs sodium carbonate softening under high pH conditions, combined with alkali-resistant PEK tubular membranes for solid-liquid separation, effectively removing calcium, magnesium, total silica, fluoride, and partial heavy metal ions. It serves as an alternative to traditional softening + sedimentation + sand filtration processes, particularly suitable for pretreatment of industrial wastewater with high hardness, high silica, and high fluoride, ensuring stable operation of subsequent NF or RO systems and reducing membrane scaling and cleaning frequency.

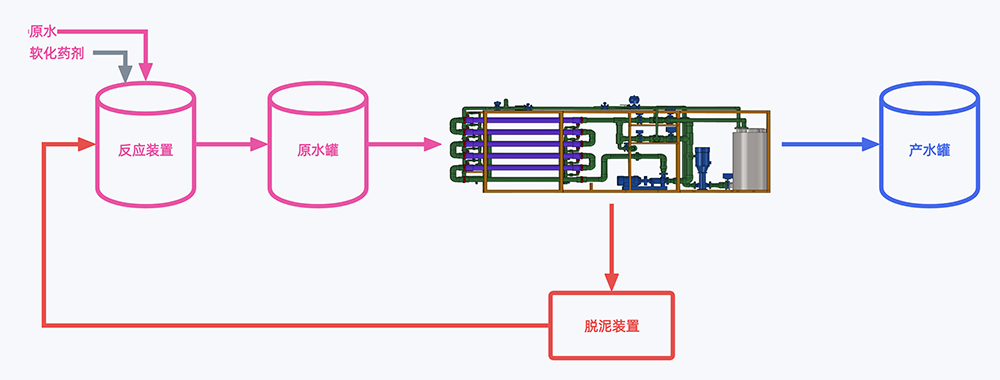

Process Flow

Raw water first enters the reaction tank, where alkaline agents (such as NaOH or lime) and sodium carbonate are added to adjust the pH to about 11.5, prompting the formation of precipitates from calcium, magnesium, and silicon ions; subsequently, the wastewater after initial sedimentation directly enters the PEK tubular membrane system, using cross-flow filtration to efficiently remove sludge and fine suspended solids, with permeate hardness stably less than 50 mg/L and total silica content less than 10 mg/L, which can directly enter the subsequent NF/RO unit. The concentrate portion enters the sludge concentration system, and after dewatering treatment, it is transported off-site, with the filtrate returned to the front-end softening tank; the entire system achieves an actual water recovery rate close to 100%, effectively improving water resource utilization and economic efficiency.

Process Flow Comparison

Process Highlights

Applications

Case Photos

Hardness & silica removal in chemical wastewater reuse

Silica & hardness removal from RO brine of mine water

Mine water hardness removal

Desulfurization wastewater: hardness & sulfate removal in power plants

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China