Introduction

Fructose-glucose syrup is a type of sweetener widely used in industries such as food, beverages, and dairy products. Based on fructose content, it can be classified into specifications like F42, F55, and high-fructose type (F90). Plum Membrane Technology Co., Ltd. employs continuous membrane separation and refining processes to achieve decolorization and impurity removal from saccharification liquids, as well as efficient clarification, concentration, and purification of fructose-glucose syrup after fructose isomerization. This enhances product purity and recovery rates, ensuring that fructose products of various grades meet national or export standards, satisfying large-scale production demands.

Background & Challenges

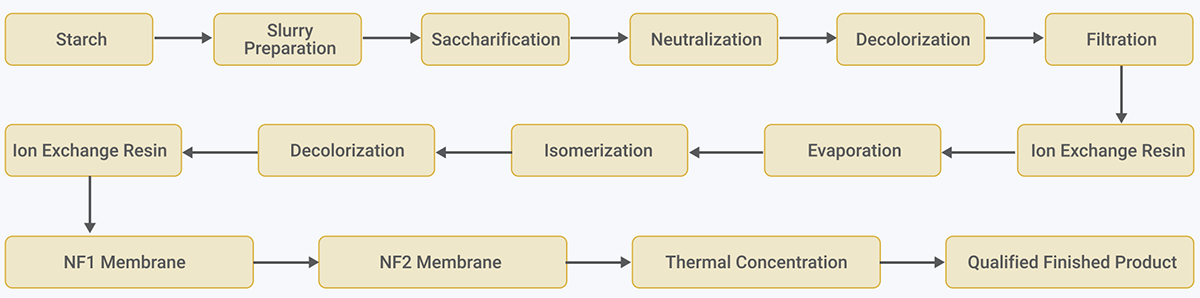

Process Flow

Starch undergoes slurrying and saccharification to convert into sugar-containing liquid, followed by neutralization to remove acidic substances, and then initial decolorization and filtration to eliminate impurities and pigments. Subsequently, the liquid enters a resin treatment system for further removal of ionic impurities, enhancing purity. Next, isomerization converts part of the glucose into fructose, increasing sweetness. The isomerized liquid then undergoes evaporation concentration to raise sugar concentration. Further decolorization removes residual pigments, followed by additional resin treatment for purification. Afterward, it enters primary and secondary nanofiltration membrane purification systems to effectively remove small-molecule impurities such as disaccharides, oligosaccharides, and hydroxymethylfurfural (HMF), improving product purity. Finally, thermal concentration yields high-purity fructose-glucose syrup, which is dried and packaged into premium products meeting food-grade requirements. The entire process achieves efficient continuous purification, quality enhancement, and stable production of fructose-glucose syrup.

Process Highlight

Fructose-Glucose Syrup Stage (F42–F55)

High-Fructose Syrup Stage (F90)

Applications

Case Photos

14m³/h High-Fructose Syrup Continuous Purification Filtration Equipment

10m³/h (20% Brix) Fructose-Glucose Syrup Continuous Purification Filtration Equipment

9m³/h (25% Brix) Fructose-Glucose Syrup Continuous Purification Filtration Equipment

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China