Introduction

During the evaporation and concentration process of lactic acid, the condensate may retain a certain amount of lactic acid (approximately 0.5%–1%). Direct discharge or secondary concentration via evaporators not only results in lactic acid loss but also increases energy consumption and treatment costs. Plum Membrane Technology Co., Ltd. employs high-retention, acid-resistant tubular membranes to concentrate and recover dilute lactic acid solutions, significantly improving lactic acid recovery rates while saving subsequent energy consumption, achieving a win-win in economic benefits and environmental goals.

Background & Challenges

Process Flow

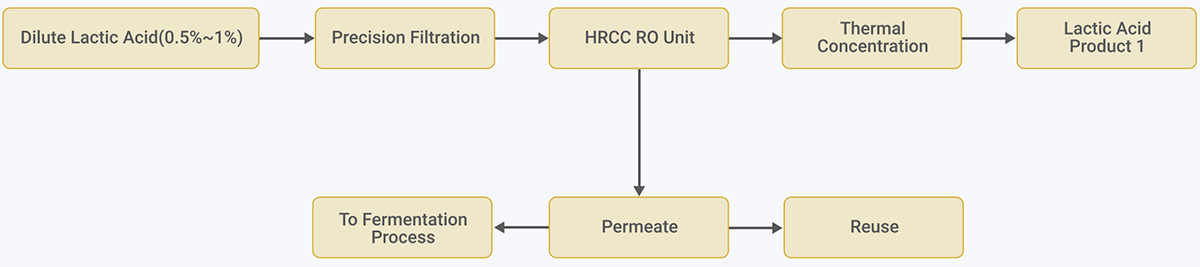

The low-concentration lactic acid solution (0.5%–1%) first undergoes precision filtration to remove suspended impurities and colloids, ensuring stable operation of subsequent membrane systems. It then enters a continuous concentration membrane system for efficient concentration of the lactic acid solution, with the produced water reusable as fermentation process water or other production recycle water, achieving water resource circulation. The concentrated lactic acid solution further undergoes thermal concentration to increase lactic acid concentration, ultimately yielding high-purity lactic acid product 1. The entire process integrates membrane concentration and water reuse, significantly reducing evaporation load and overall energy consumption while enabling efficient lactic acid resource recovery and closed-loop circulation of process water.

Process Highlight

Applications

Case Photos

40m³/h Dilute Lactic Acid Membrane Concentration System

55m³/h Dilute Lactic Acid Membrane Concentration System

No. 55 Wuliu Avenue, Xinzhan Hi-Tech Zone, Hefei, Anhui, China