language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Technology

PEK technology

Compared with PVDF membrane, PLUM Co pioneered the development of tubular membrane made of PEK.PEK tubular membranes combine alkali resistance and high suspension resistance.

What ‘s PEK?

Polyetherketone (PEK) is a ketone-based semi-crystalline high-performance engineering thermoplastic. PEK's high thermal dimensional stability, low flammability, excellent chemical resistance, and excellent mechanical properties over a wide temperature range make it commonly used in high-standard applications in a variety of markets.

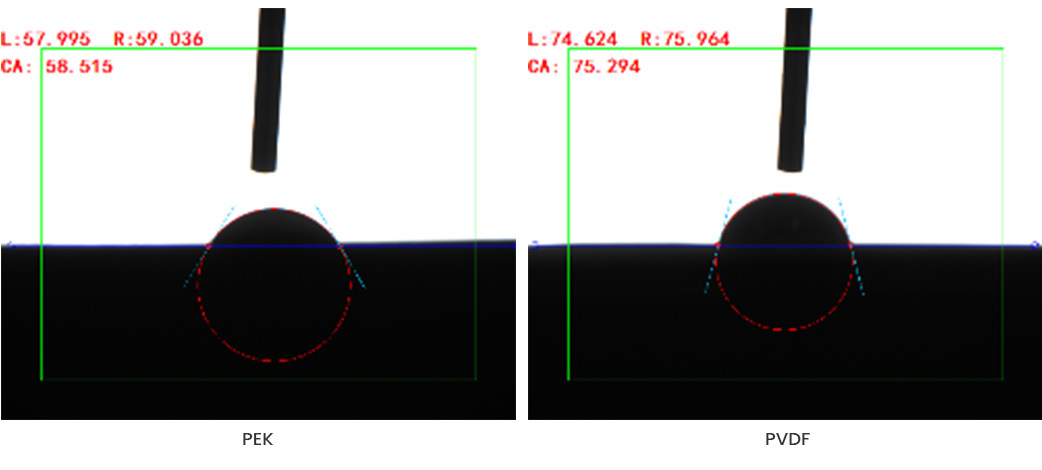

Hydrophilic comparison of PEK and PVDF

Performance parameter comparison

| Membrane material | PVDF | PEK | ||

| Nominal pore size | Unit | 0.2nm | 30nm | 50nm |

| Pure Water Flux | LMH,100kPa | 1500 | 900 | 1200 |

| Operating Pressure | kPa | -50~800 | -100~1000 | |

| Max. Operation T | ℃ | 65 | 65 | |

| pH-range |

|

2~10 | 1~14 | |

| Chlorine Exposure | ppm·h | 250000 | 300000 | |

Recommended product

1.High-quality non-woven fabric and double-sided welding technology

2. Exclusive PEK material

2.Chemical resistance

2.Superior hydrophilicity

3.Strong anti-pollution ability.

4.As a pretreatment process, the effluent quality is stable with turbidity less than 0.5 NTU and SDI less than 4.

Learn More

Hefei-Anhui-China

Hefei-Anhui-China +8618226169015

+8618226169015 haoyangyu@plummembranes.com

haoyangyu@plummembranes.com

haoyangyu@plummembranes.com

haoyangyu@plummembranes.com

8618226169015

8618226169015

Message

Message